Maintenance and repair for WEISS spindle units

We use the experience and expertise that we gain from carrying out more than 3,000 spindle repairs each year for your benefit.

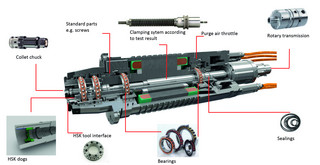

Like any mechatronic system, spindle units and spindle components are also subject to wear. Once the wear limit has been reached or an overload (e.g. collision) has occurred, the spindle unit can be technically repaired as good as new.

In most cases, current spindle units in machining centers are designed as so-called slide-in spindle units and can thus be replaced as a complete unit. If required, you can also fall back on our experienced service teams, which can also support you here at short notice.

For subsequent maintenance or repair, we keep a range of spare parts in stock at our manufacturing plant.

The availability of repair and spare parts is extremely important for short-term maintenance. We therefore recommend securing this availability by concluding a service agreement, which brings further individual advantages for the customer. In addition to the advantage of securing the availability of spare parts, a service agreement brings further individual advantages for the customer.

Repair process

We will confirm receipt of your spindle unit at our premises shortly after delivery.

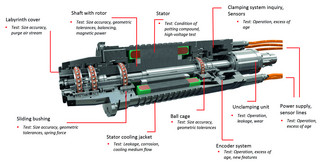

The subsequent incoming inspection allows initial conclusions to be drawn about the scope of repairs.

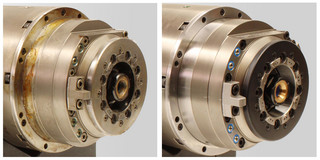

At Weiss, we attach particular importance to gentle disassembly using suitable tools and devices in order to avoid damage to the components and to be able to draw conclusions about the cause of the damage that are as unbiased as possible.

In the findings report, we present component damage and give you a recommendation regarding component repair or replacement. Based on these recommendations, we submit an individual repair offer and coordinate it with you. To reduce your administrative workload, we can set standards for recurring damage patterns and repair offers, right up to flat-rate repairs, in a service agreement.

On our modern test stands, every repaired spindle unit undergoes the same automated test run as a new spindle. Extensive data is recorded to ensure that the mechanical, electrical and thermal properties are in order and that the acceptance criteria agreed with the customer are met. We can offer you a customer-specific special test thanks to our wide range of drive options (Siemens/Heidenhain/AMK/standard frequency converters).

Before the spindle unit leaves our premises again, we confirm the result of the inspection in a test certificate. In addition, the spindle unit is provided with a QR code for the spindle identifier.

Securely packed in our special wooden crates, which are also suitable for overseas transport and have been designed for stockpiling at the customer, the spindle unit starts its return journey to you. Alternatively, storage in our spindle hotel is possible.

Your personal account manager will be happy to advise you on the possibilities of cooperation.

Call us. We will be pleased to assist you.

Our experienced team will provide you with rapid assistance, whatever your inquiry.

Service hotline: +49 9532 9229-347 or service-weiss@innomotics.com