WEISS Spindle SiS+

Detection chip in spindle - Automatic clamping force monitoring

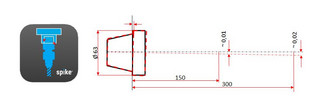

SiS+ is a spindle integrated system for chip in spindle detection and automatic monitoring of the clamping force of an HSK A63 tool interface.

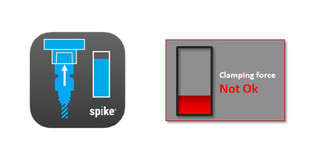

With the optional SiS+ interface, machining errors caused by a chip between the spindle and the tool holder can be detected immediately after the tool change and before machining, and associated dimensional inaccuracies on the workpiece can be excluded. The same measurement is also used to check the clamping force. Insufficient clamping force is detected at an early stage and appropriate maintenance measures can be carried out before inaccuracies in machining quality or even spindle failure occur.

Functionality

After changing tooling

- Automatic detection of chips at the HSK interface

- Both PLAN & CONE surface

- Automatic clamping force control

Highlights

- Reduction of machining errors

- Increased process reliability

- Improved surface quality

- With existing tool cone cleaning, a new cone cleaning can be initiated when a chip is detected -> avoidance of machine stoppage

- Decreasing clamping force is detected and indicated at an early stage by monitoring

Results of fault because of radial displacement

Dectable chip thickness (axial) ≥ 10 µm

Results if clamping force to small

- Vibrations

- Increased tool waste

- Tool damage