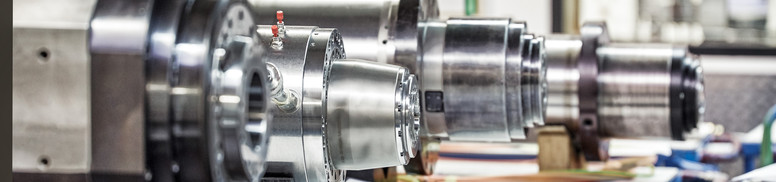

B axis

The B axes produced by WEISS are individually adjusted for attachment of adapter spindles. In this process, we particularly set benchmarks in terms of precision, rigidity, and stability under load.

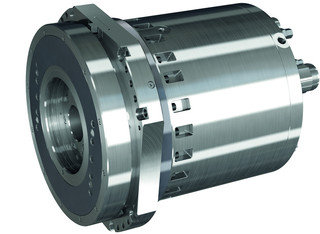

Bearings

The bearing used is a two-way acting axial roller bearing that ensures highest rigidity rates and load rating due to its design, making it the ideal type of bearing for this type of application.

Positioning range

Depending on the passage of media and electrical energy, positioning angles of +/- 120 ° are currently implemented.

Motor

The B axis is driven by water-cooled high-pole torque motors. The motors are designed as permanent-magnet synchronous motors and are capable of achieving very high torques in very restricted installation space.

Clamping system

B axis are typically equipped with a clamping system for clamping and or arresting of the shaft. This is required to ensure the fail-safe function and/or for increase of the holding torque during machining. The clamping system comprises radially acting clamping sleeves for infinitely variable clamping and/or Hirth serrations (defined segmentation) for the highest holding torques of up to 15,000 Nm. To combine the benefits of these systems, we are able to equip B axes with both systems at the same time. In this case, operation of the clamping systems can be performed either by hydraulics or by pneumatics.